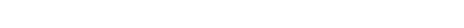

The basic structure of tatami is simple, comprising Toko (base), omote (cover), and heri (border).

The base (tatami toko) is made of multilayered rice straw, tightly fastened, and compressed. The cover (omote) is natural igusa (rush). Tatami consists basically of a base, omote and heri edges crafted in to a rectangle. While this is a very simple explanation there are numerous other intricate elements used.

Now there are various new materials to make tatami but the basic idea hasn’t changed for centuries. Here are some features of the base, omote and heri.

1 Tatami-toko(base)

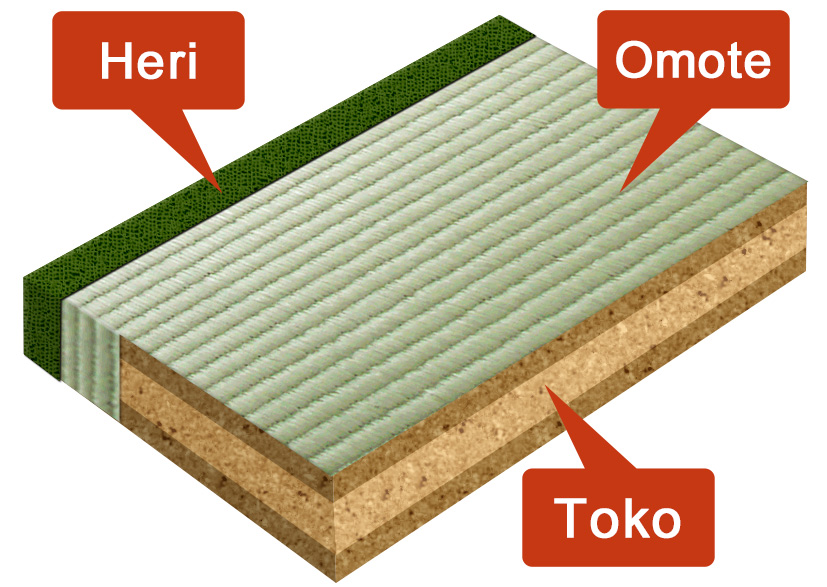

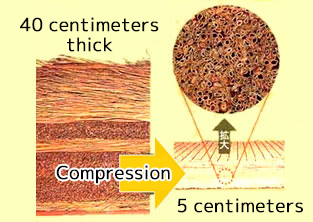

Traditionally, the base is been made of ‘wara-toko’ (base – multilayered 100% natural rice straw). However, due to changes in application and demand the base no also can be made of made of light building materials like, styrofoam sandwiched between compressed wood-chip board.

Wara-toko (Natural straw base)

Ranking of Natural Base

There are three categories of natural base. The more natural material used in the manufacture determines the cost and quality.

The high grade natural base has a fixed thickness, without any irregularity or unevenness on surface, the material used to create this base is of the highest quality. It is sewn finely so it is resilient. Furniture can be placed for long periods on this base, it will resume its natural shape once the furniture is moved, this is due to the air in the base. The better the quality of the base the longer it will last, another factor in its life span is if is ventilated and dried appropriately. Natural base is more economical in the long term.

Second grade base

Third grade base

| Grade | QualityWeight (92W) g | Clearance of yarn (c㎡) | Purpose | |

|---|---|---|---|---|

| Best quality natural base | the best quality there is. | 30.4〜34.6 | 8.0 or less | Used in tea rooms, shrines & temples |

| High quality natural base | uper-high grade quality. | 28.2〜32.4 | 8.1〜9.5 | Used in high-class residential projects. |

| Natural base | second-grade. | 26.0〜30.2 | 9.6〜12 | Better than average quality. Highest demand, used for homes. |

| Multipurpose | third-grade. | 23.8〜28 | 12.1〜14.5 | Popular for apartments and low cost jobs. |

Sandwich base (Styrofoam)

Styro-toko comprises polystyrene foam sandwiched between straw. This has similar feeling to natural base and is lighter than the total natural base. This option has better humidity resilience than natural base.

As the grades of base differ, so does the straw included in the manufacture. The sandwich base uses ‘Gomoku’ (crushed straw). The natural uses lengths of straw – increasing the quality and strength.

Top class sandwich base

Standard sandwich base

Kenzai-toko (Building material base / non-natural)

There are three types of non-natural base: insulation board made of compressed wood-chips; polystyrene foam sandwiched with board, and 100% board.

This options features: cheap, light-weight, good insulation and resistance to moisture. It also is resistant to mites and bugs. However, it is harder underfoot and less durable.

All board

Board sandwich

Board and foam

All board 15mm thick

2 Tatami-omote(cover)

Omote is graded. The highest grade of omote is generally found in scared places like shrines and temples, wealthy homes, and important spaces.

To gain a premium grade the omote has to be made from igusa of a certain length, quality and weave. High quality omote has four hemp strings, two at each weave, binding the igusa together, and is generally made of two mats weaved together in the centre; this forms a thick, strong mat. High quality Igusa used in these mats is only harvested once a year.

The most commonly used omote in Japanese homes and for international clients is the high to mid grades; this omote is still a premium product but is more readily available. The lower grades vary. There are still good products at this level. These mats do tend to have a shorter life span. This omote is good for areas of high use, where mats will need to be resurfaced more regularly. While omote vary in quality and look, the lowest grade Japanese omote is much higher quality than any other overseas product.

Weave

Hemp or cotton yarn is used to weave the igusa.

There are various options for the material used in the weave. The strength and durability of the weaving string determines how strong the omote is. With a stronger string it also means the strand count can increase making the surface thicker creating the chevron shape. The thread count also affects the feeling underfoot. Hemp is the strongest.

Bingo (top quality) double hemp

Bingo (second grade – still classifies above other omote) Cotton and hemp

Yume-omote / cotton and linen

Asa-biki / single hemp

Chinese / double cotton

Chinese / single cotton

Effect of Igusa

Igusa tatami increases the Indoor Environmental Quality (IEQ), which includes factors like: air quality, acoustics, and humidity. Tatami filters the air in a room, absorbing carbon dioxide, increasing the Indoor Air Quality (IAQ). The mats also act as insulation both for temperature and sound. The rush weave cover (omote) absorbs or expels moisture in the room when the seasons change. This absorption regulates humidity and the temperature in the space. These qualities are essential to a relaxing, healthy living environment.

Made in China and Made in Japan

The Chinese omote has increased its market share in recent years, this is mainly due to cost. But with the lower cost it is also much lower quality. Some downsides to the Chinese product are:

- Igusa is harvested one month earlier in China than in Japan, the immaturity means it is less durable.

- In the process of drying igusa, Japanese products undergo lower temperature for a longer time. Chinese products undergo higher temperature for shorter period of time. The Chinese igusa looses moisture and becomes drier, with a shaggy surface. The elasticity is also diminished.

- The selection is made by each farm in Japan, unlike China. The Chinese grown igusa’s quality differs, and it is problematic for color. Due to this often the igusa is chemically dyed, this process removes the smell, air purifying quality and the artificial color is lost once shipped. Sometimes this material transfers color, it also is prone to sunburn, means there is not uniformity in the mats.

The Chinese product is improving but it still pails in comparison to the Japanese product.

Omote made in China

Omote made in Japan

(Upper) Made in Japan

(Lower) Made in China

There are a wide range of omote due to various uses.

There are various kinds of omote for different needs: Meseki-omote, woven finer than usual; Ryukyu-omote, made from stronger igusa called Shitto-i; omote made of chemical fiber or paper, along with others.

※(Left picture) Ryuku-I (Shitto-i)

3 Tatami-heri(border)

Heri used to be made from cotton or hemp but synthetic fiber has become mainstream these days. Synthetic cheaper and stronger, but in terms of sense of quality, the natural fiber is better. High class heri uses hemp.

Heri can be a plain single color or come with various patterns, including the special heri used for temples and the tokonoma (alcove)

About Kamachi

Kamachi 1

Kamachi 2

The shorter sides of tatami are called ‘kamachi’. If the base (toko) is simply wrapped, the corners of base will be damaged and swell.

In the past, ‘kamachi-ita (kamachi board)’ was sewn with the timber but now with more technology it can be sewn by machine. Traditional hand sewn wooden kamachi has a better end result in terms of look and quality.